Previous slide

Next slide

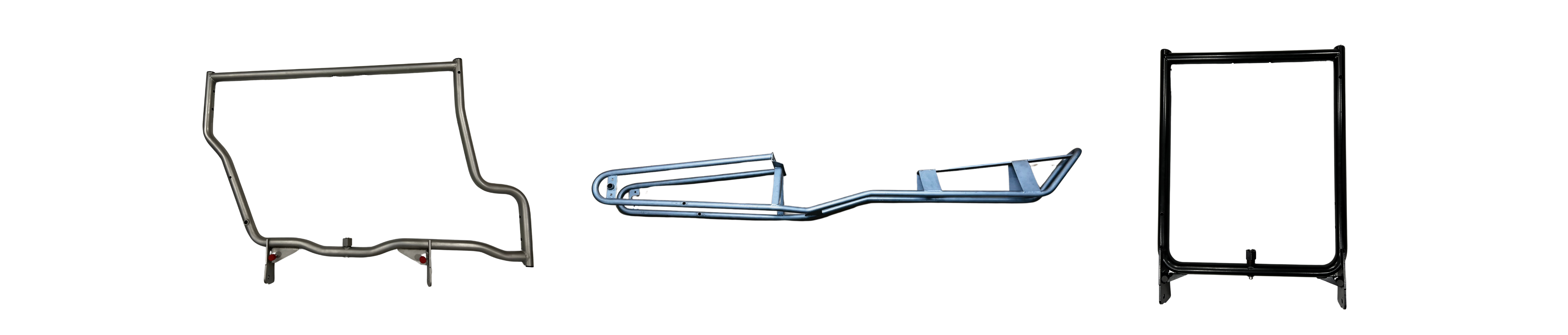

Vina Steel Fabrications is your Global source for Contract Manufacturing

VINA STEEL FABRICATIONS

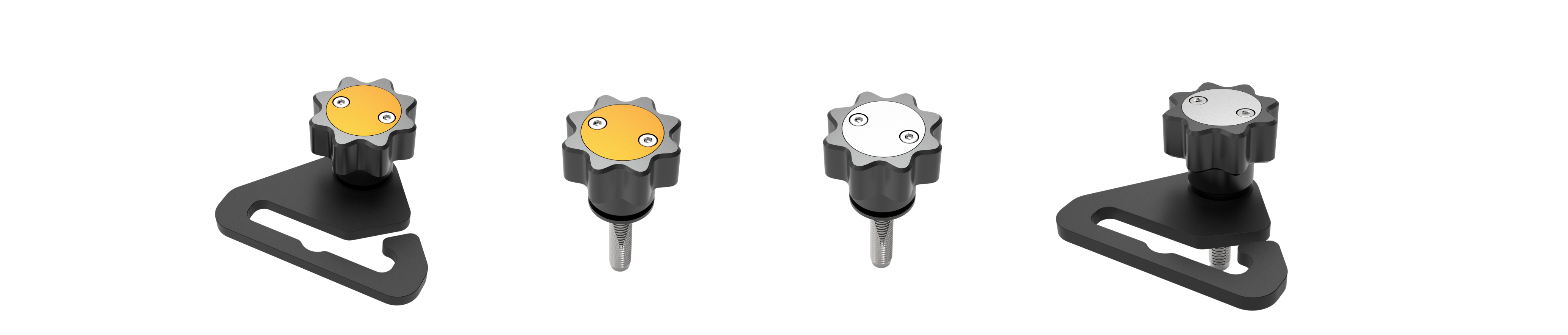

FULL-SERVICE FABRICATION & FINISHING

- Powder coating &Wet coating.

- Zinc/Nickel-Chrome Plate.

- Electropolishing.

- Sand blasting/Glass bead blasting.

WE ARE VINA STEEL FABRICATIONS

Industries We Serve

WE ARE VINA STEELFABRICATIONS

Why

choose

vnsf co.

End-to-End Service

Comprehensive support from design consultation through final packaging.

Fast Turnaround

Prototype in as little as 2 weeks, with full production completed in approximately 45 days, helping you accelerate time-to-market.

IP Protection

Strict NDAs and internal controls to protect your intellectual property.

Cost-Effective Quality

Efficient Vietnam manufacturing aligned with international quality standards.

US-Friendly Partnership

English-speaking team with support during US business hours.

Quality Guaranteed

Consistent quality control, including batch testing and final inspections follow PPAP procedure.

Get A Free Quote For your Project